What role does the display driver IC play in the LED display?

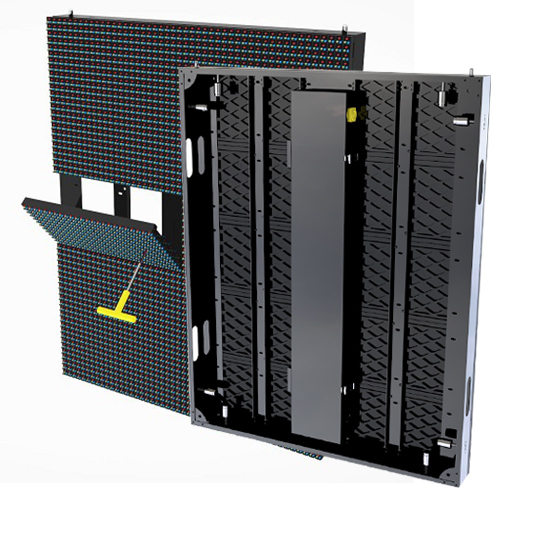

Many ICs can be seen on the PCB board on the back of the LED display. What influence and effect will these LED display driver ICs have? This article will introduce you to the role played by ED display driver ICs, as well as energy-saving and integration trends.

The role of the driver IC in the full-color LED display is to receive the internal production time PWM protocol to display data (receive video card or processor information from the source).

The current output brightness level refresh and other related PMW current can light up the LED, and the display driver IC, logic IC and display peripheral supporting IC work together on the LED display and determine its current display status.

LED driver chip categories: general-purpose and special-purpose

The general-purpose chip itself is not specifically designed for LEDs, but some logic chips have the logic function of the LED display part.

The dedicated chip is a chip specially designed for LED display drive according to the luminous characteristics of the LED. LED devices with current characteristics, that is, under the premise of saturated conduction, the brightness will change with the change of the current, rather than by adjusting the voltage across it. Therefore, one of the characteristics of the dedicated chip is to provide a constant current. Constant current can ensure the stability of the LED drive and eliminate the flicker of the LED, which is a prerequisite for high-quality LED display. Some dedicated chips for different industries have also added some special functions, such as current correction functions with LED error detection and current gain control.

Driver IC development

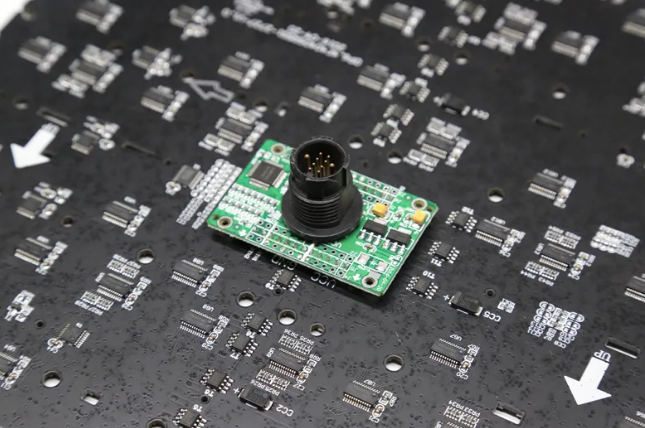

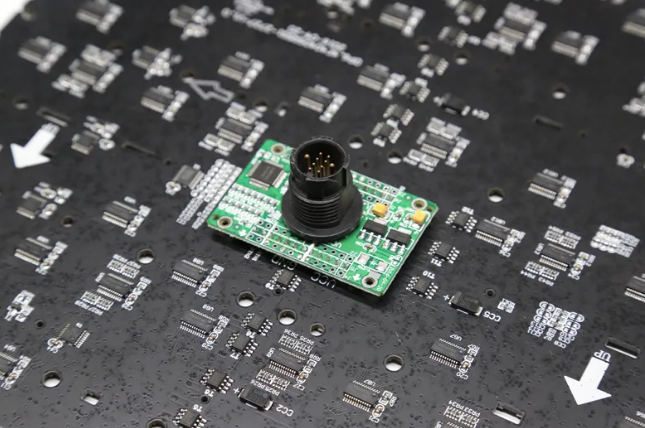

In the 1990s, LED display applications were based on monochrome, using constant voltage drive ICs. In 1997, China experienced the first-generation LED display dedicated driver IC 9701, with a gray scale ranging from 16 to 8192, achieving what you see is what you get. Subsequently, the luminous characteristics of LED constant current drive became the choice of full-color LED display drive, and the more integrated 16-channel 8-channel drive replaced this drive. In the late 1990s, companies such as Toshiba of Japan, TI of the United States, and Riyuecheng of China successively introduced 16-channel constant current LED driver chips. By the beginning of the 21st century, companies in Taiwan had also begun the production and use of driver chips. Now, in order to solve the PCB wiring problem of the small-pitch LED display, Riyuecheng has launched a highly integrated 32-scan 48-channel constant current LED driver chip.

Driver IC performance

Among LED display performance indicators, image refresh rate and grayscale expression are one of the most important indicators. This requires that the current between channels of the LED display driver IC has a high consistency, a high-speed communication interface rate and a constant response speed. In the past, the relationship between refresh rate, grayscale, and utilization has changed. By sacrificing one of them to ensure that one or two of the indicators can perform better. Therefore, it is difficult for many LED display screens to achieve both in practice. Either the refresh is not enough, the high-speed camera equipment is prone to black lines, or the grayscale is not enough, and the color is inconsistent. With the development of technology driving the development of IC R&D level, these problems can now be solved. In the application of LED full-color display screens, in order to ensure long-term eye comfort for users, low brightness and high ash content have become a particularly important standard for testing the performance of driver ICs.

Driver IC trends

1. Energy saving

Green energy saving is the eternal pursuit of LED displays, and it is also considered an important criterion for the performance of driver ICs. Driving IC energy saving includes two aspects. One is to reduce the inflection point voltage and constant current; the other is to reduce the operating voltage and operating current through optimized algorithms and IC design. Riyuecheng’s pioneering Idle Stop (dynamic low power consumption) energy-saving technology enables less power consumption, lower screen temperature, and black screen standby to save power, which is especially suitable for the use of LED displays that work continuously for 7*24 hours.

High integration

With the rapid decline of the pixel pitch of the LED display screen, the number of packaged devices installed has increased exponentially, which has greatly increased the component density of the module. For example, in the small-pitch P1.9 LED, 15 scans 160 * 180, and 90 modules require 45 lines of constant current drive ICs, 2138. So many available devices make PCB wiring space extremely crowded, thereby increasing the difficulty of circuit design. At the same time, such a cumbersome component layout can easily lead to problems such as poor soldering and reduce the reliability of the module. The smaller the number of driver ICs, the larger the PCB layout area. Therefore, the application requirements of driver ICs must be pushed to a highly integrated technology roadmap. In recent years, Riyuecheng has been committed to the research and development of highly integrated ICs, reducing the overall IC usage ratio by 71% compared to the traditional ones. It also reduces the area of the IC itself, reduces the PCB footprint, and brings customers Less is more. Effect.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик